GRS Consulting

Fonterra Kauri K1 and K2 Dryer Safety Upgrades

Modern dryer systems have intensive safety systems, owing to the significant risk of explosive conditions in their processes. These systems include independent monitoring and control of key parameters. The Kauri plant upgrades were implemented in two dryers over four years, during winter shutdowns, with challenging timeframes. Design and documentation was to SIL2 levels.

Electrical engineering design you can trust

Call 09 410 8393 or Contact Us

DRYER SAFETY SYSTEMS - KAURI

FONTERRA KAURI

DAIRY INDUSTRY

INSTRUMENTATION AND CONTROLS

More Case Studies

Ammonia Engine Rooms Hazardous Areas

We designed and implemented ammonia engine room hazardous area monitoring and control upgrades for 6 engine rooms across the Te Rapa site, implementing Fonterra’s strategy for standardised controls.

Lighting Control – Storage King

The building owner requested us to investigate the cause of unusually high electricity bills in this large multi-storey storage facility.

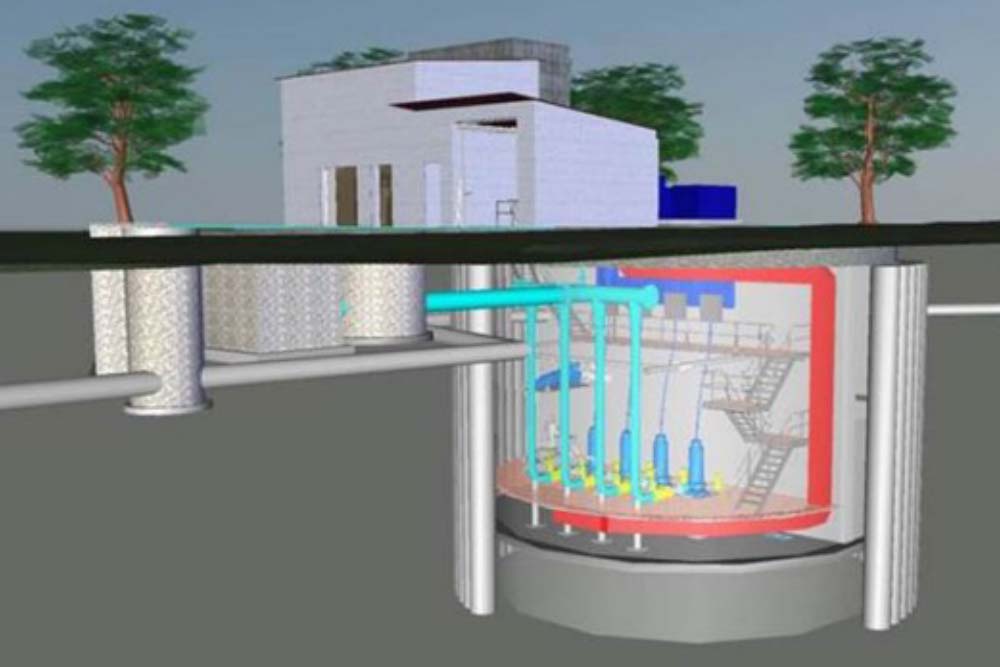

Watercare Services – Mairangi Bay Wastewater Pumpstation

The Sidmouth Street Mairangi Bay wastewater pumpstation is a Watercare key facility, collecting and pumping all the North Shore’s east coast bays sewage to the Rosedale treatment works.