GRS Consulting

Fonterra Kauri Natural Gas Hazardous Area Classification

Natural Gas represents a significant risk across some industrial sites because mains gas is piped extensively and used for raising process steam and hot water in packaged boilers. Simple methods of classification can over-assess or under-assess the risks, leading to underestimation of where the real risks are, or unnecessary over-expenditure where there are less risks. Our approach for these areas is to use the latest empirically based methods in hazardous area classification, including calculation tools, and to analyse the ventilation in the key areas. This approach enabled us to produce more accurate zone drawings and identify ventilation parameters and controls for the Kauri site.

Find out more about our solutions for

Hazardous AreasElectrical engineering design you can trust

Call 09 410 8393 or Contact Us

GAS HAZARDOUS AREAS - KAURI

FONTERRA KAURI SITE

DAIRY INDUSTRY

HAZARDOUS AREAS

More Case Studies

Complete Electrical Services – Synlait

We designed the complete electrical system, to cater for shared services for the various process and building contractors and achieved an integrated result.

Lighting Control – Storage King

The building owner requested us to investigate the cause of unusually high electricity bills in this large multi-storey storage facility.

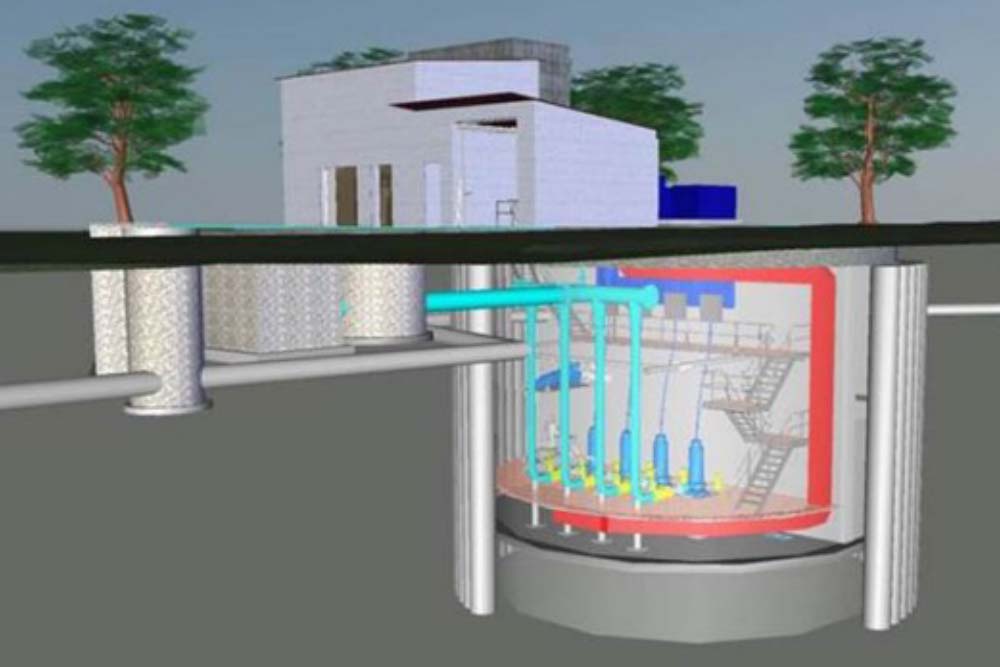

Watercare Services – Mairangi Bay Wastewater Pumpstation

The Sidmouth Street Mairangi Bay wastewater pumpstation is a Watercare key facility, collecting and pumping all the North Shore’s east coast bays sewage to the Rosedale treatment works.