GRS Consulting

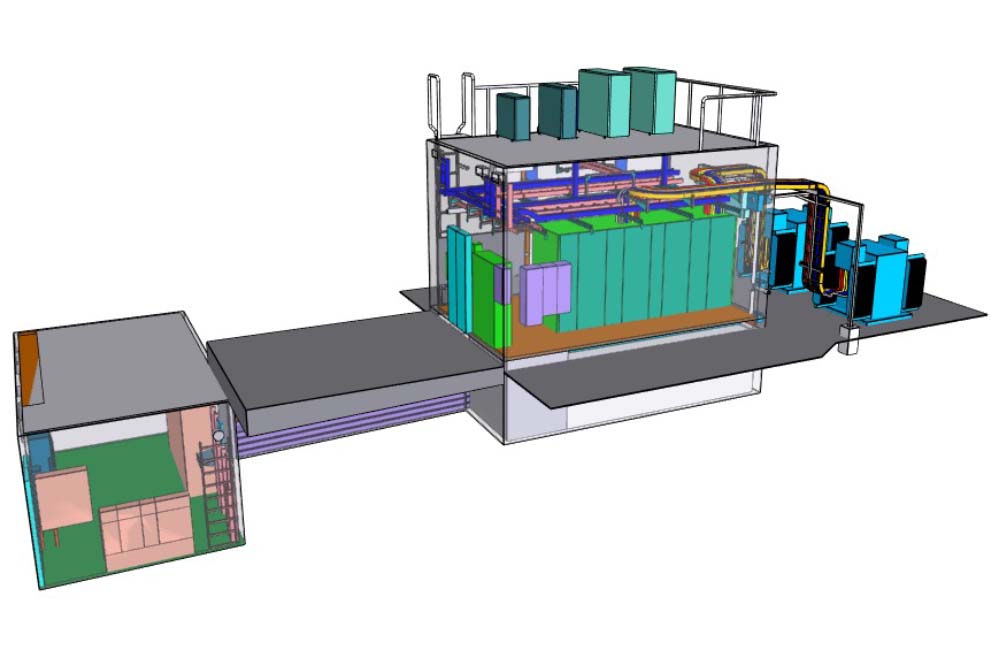

Fonterra Maungaturoto Whey Plant MCC Replacement and Plant Rewire

The Whey Plant was automated, rewired and had the MCC’s replaced in 2009. Our scope included the design of the electrical services and associated work. We designed an MCC which was more spacious, cleaner, and more serviceable, with spare capacity. The switchgear migrated from three single sided boards to one double sided assembly. MCC ladderack was redesigned, and new runs into the plant provided more space and hygienic supports.

Electrical engineering design you can trust

Call 09 410 8393 or Contact Us

MCC REPLACEMENT - MAUNGATUROTO

FONTERRA MAUNGATURO SITE

DAIRY INDUSTRY

POWER DISTRIBUTION AND MOTOR CONTROL

More Case Studies

MCC Replacement – Kauri

This project required replacement of the most critical switchboard on site within a 7 week shutdown, including associated building and HVAC upgrades.

Gas Hazardous Areas – Kauri

Natural Gas represents a significant risk across some industrial sites because mains gas is piped extensively and used for raising process steam and hot water in packaged boilers.

Ammonia Engine Rooms Hazardous Areas

We designed and implemented ammonia engine room hazardous area monitoring and control upgrades for 6 engine rooms across the Te Rapa site, implementing Fonterra’s strategy for standardised controls.