GRS Consulting

Fonterra Maungaturoto Dust Hazardous Area Classification and Upgrades

Over the course of 5 years, we classified hazardous areas and designed systems for the upgrading of hazardous area equipment and systems across the site. This included Casein, Whey, Powder, Bins, and Packing Plants. Particularly challenging was 2 packer upgrades over two short maintenance shutdowns during the Covid lockdowns in 2020.

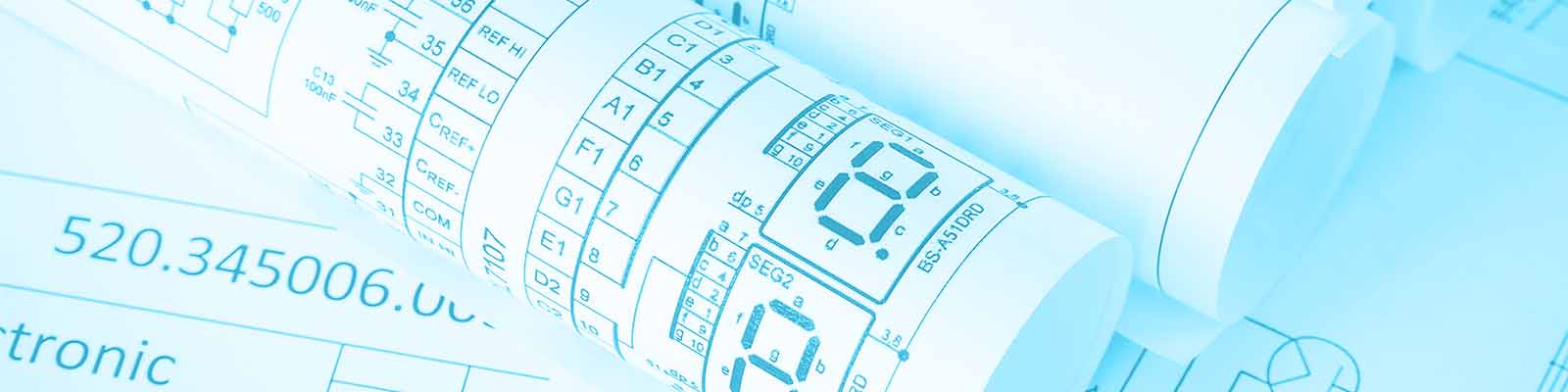

Electrical engineering design you can trust

Call 09 410 8393 or Contact Us

More Case Studies

Dryer Safety Systems – Kauri

Modern dryer systems have intensive safety systems, owing to the significant risk of explosive conditions in their processes.

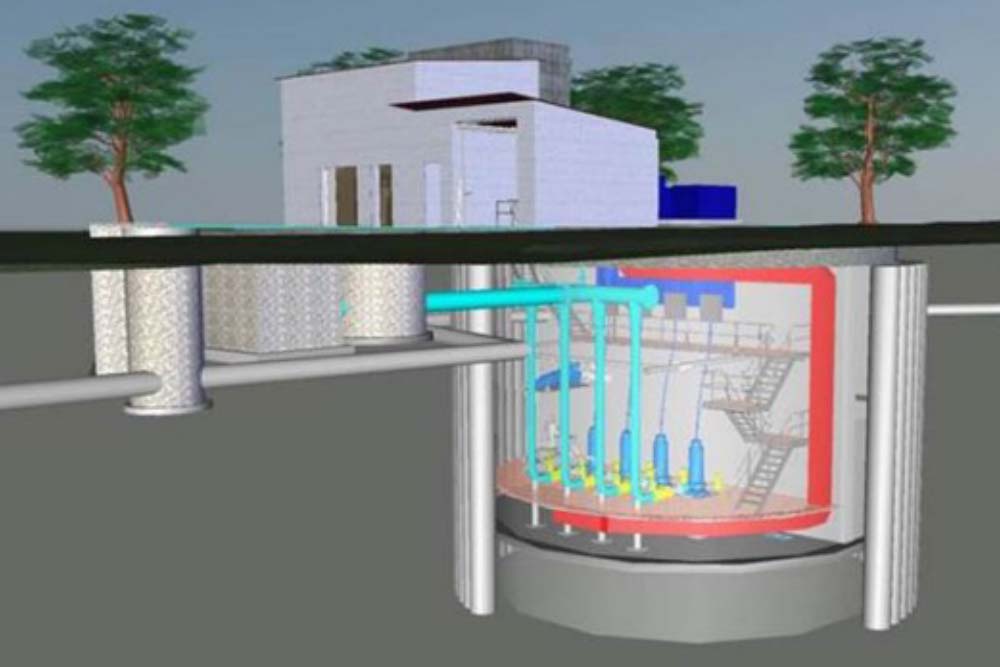

Watercare Services – Mairangi Bay Wastewater Pumpstation

The Sidmouth Street Mairangi Bay wastewater pumpstation is a Watercare key facility, collecting and pumping all the North Shore’s east coast bays sewage to the Rosedale treatment works.

Complete Electrical Services – Synlait

We designed the complete electrical system, to cater for shared services for the various process and building contractors and achieved an integrated result.